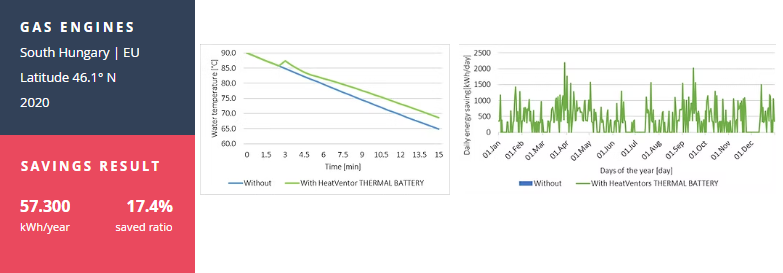

Introduction

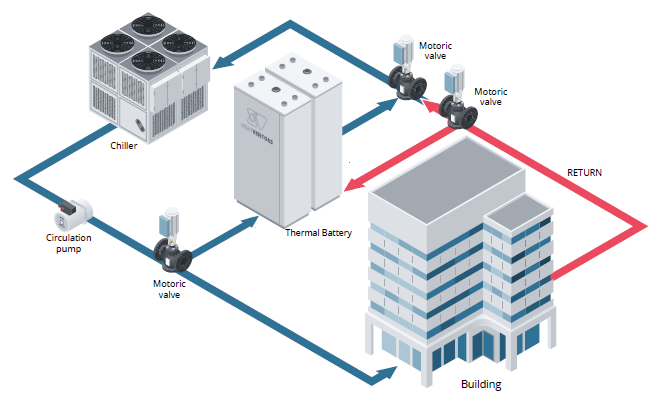

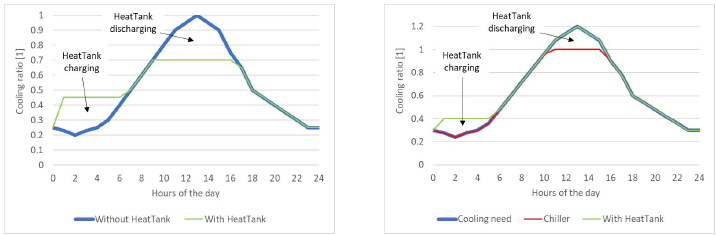

HeatVentors’ technologies are patented, customisable mechanical designs as well as the optimisation and control algorithms which provides the ability for quick intervention to control intelligence.

As Cooling system, like air-conditioning, typically account for around 30~40% of the entire building’s electricity bill, making it the largest contributing factor.

Benefits

HeatTank is revolution in thermal energy storage systems.

-

- 3 – 5 Years ROI

- 20-50% CO2 Emission Cut

- 25+ Years Lifetime with Excellent Reliability

- Energy Efficiency

- Excellent Back-up Cooling System

- 20-50% reduction in CO2

- Auditable Energy Report

- 90% Space saving